About Design & Engineering Services

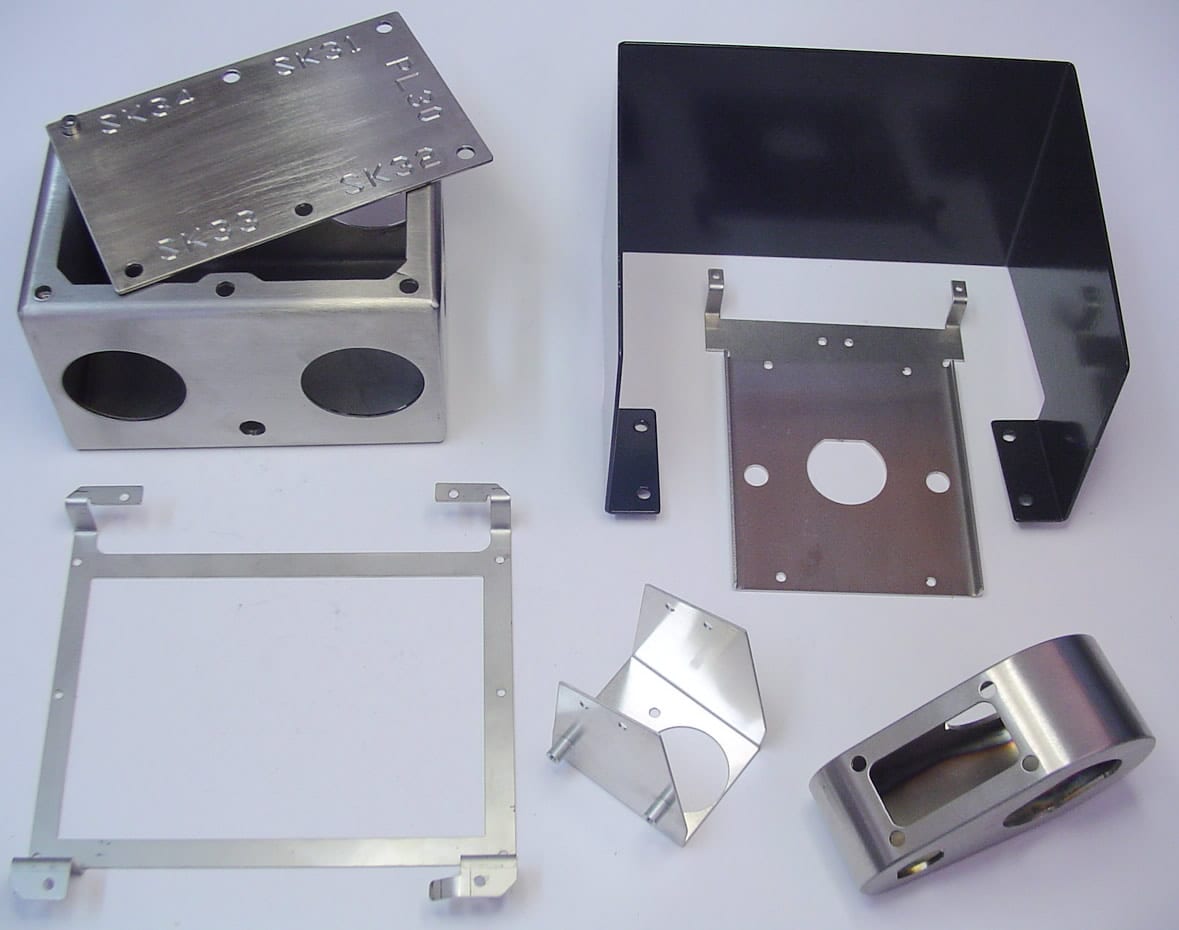

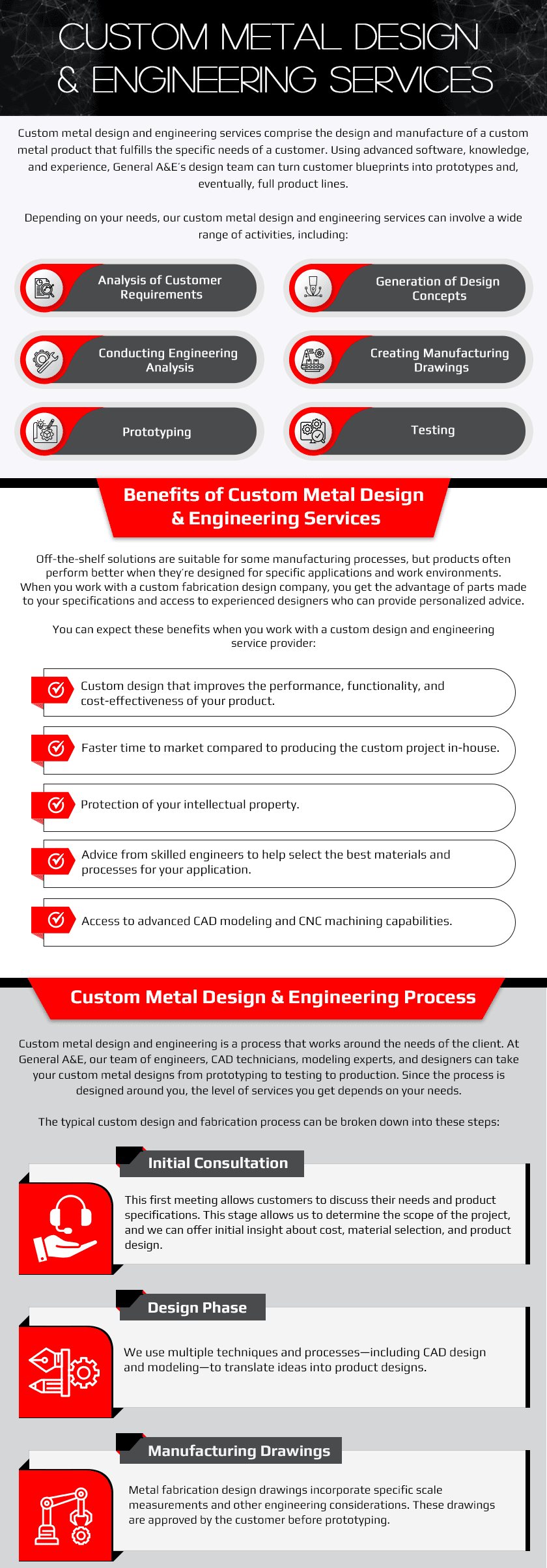

Custom metal design and engineering services comprise the design and manufacture of a custom metal product that fulfills the specific needs of a customer. Using advanced software, knowledge, and experience, General A&E’s design team can turn customer blueprints into prototypes and, eventually, full product lines. Depending on your needs, our custom metal design and engineering services can involve a wide range of activities, including:

- Analysis of customer requirements

- Generation of design concepts

- Conducting engineering analysis

- Creating manufacturing drawings

- Prototyping

- Testing

Benefits of Custom Metal Design & Engineering Services

Off-the-shelf solutions are suitable for some manufacturing processes, but products often perform better when they’re designed for specific applications and work environments. When you work with a custom fabrication design company, you get the advantage of parts made to your specifications and access to experienced designers who can provide personalized advice.

You can expect these benefits when you work with a custom design and engineering service provider:

- Custom design that improves the performance, functionality, and cost-effectiveness of your product

- Faster time to market compared to producing the custom project in-house

- Protection of your intellectual property

- Advice from skilled engineers to help select the best materials and processes for your application

- Access to advanced CAD modeling and CNC machining capabilities

Custom Metal Design & Engineering Process

Custom metal design and engineering is a process that works around the needs of the client. At General A&E, our team of engineers, CAD technicians, modeling experts, and designers can take your custom metal designs from prototyping to testing to production. Since the process is designed around you, the level of services you get depends on your needs.

The typical custom design and fabrication process can be broken down into these steps:

- Initial Consultation: This first meeting allows customers to discuss their needs and product specifications. This stage allows us to determine the scope of the project, and we can offer initial insight about cost, material selection, and product design.

- Design Phase: We use multiple techniques and processes—including CAD design and modeling—to translate ideas into product designs.

- Manufacturing Drawings: Metal fabrication design drawings incorporate specific scale measurements and other engineering considerations. These drawings are approved by the customer before prototyping.

- Prototyping: We produce a physical prototype based on the design and manufacturing drawings.

- Testing: The models or prototypes are then tested and refined, ensuring they comply with customer and industry requirements. This stage is a cost-effective way to verify the functionality, aesthetics, and manufacturability of the custom product before moving into production.

- Production: When your design is ready for manufacturing, it will produced to your specifications.

Custom Metal Design & Engineering by General A&E

General A&E’s exceptional engineering and manufacturing services are available with competitive pricing and fast lead times. With decades of experience, advanced software, and state-of-the-art machinery, we can provide complete part development for a wide range of industries. To get started on your project, request a quote for our custom metal design and engineering services.