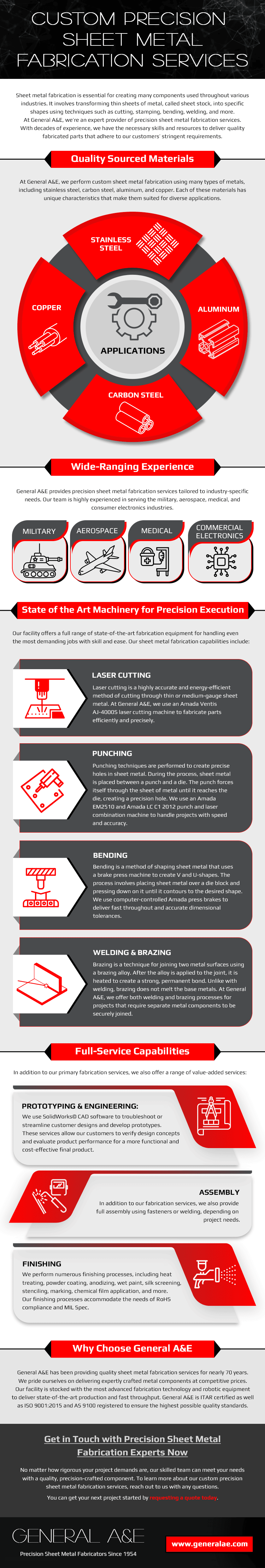

Sheet metal fabrication is essential for creating many components used throughout various industries. It involves transforming thin sheets of metal, called sheet stock, into specific shapes using techniques such as cutting, stamping, bending, welding, and more. At General A&E, we’re an expert provider of precision sheet metal fabrication services. With decades of experience, we have the necessary skills and resources to deliver quality fabricated parts that adhere to our customers’ stringent requirements.

Quality Sourced Materials

At General A&E, we perform custom sheet metal fabrication using many types of metals, including stainless steel, carbon steel, aluminum, and copper. Each of these materials has unique characteristics that make them suited for diverse applications.

Stainless Steel

Composed of carbon steel, aluminum, and a high chromium content, stainless steel is highly resistant to corrosion and features a unique lustrous appearance. Since it is durable and can be sterilized, it is a common material for producing medical items. It is also used in cookware, appliances, cabinet fittings, and much more.

Aluminum

Aluminum is a lightweight and versatile material that performs very well in subzero temperatures. It also features excellent thermal and electrical conductivity. Due to these characteristics, it is widely used throughout the aerospace industry, as well as in refrigeration applications.

Carbon Steel

Carbon steel has a higher carbon content than other steel varieties, which gives it a lower melting point. It is more malleable and durable than other types of steel and can withstand harsh environmental conditions. Carbon steel is a commonly used material in metal fabrication and is a popular choice for applications that demand strength and sturdiness.

Copper

Copper is highly resistant to corrosion and an excellent conductor of electricity. As a malleable and durable material, it is widely used throughout industrial and marine applications.

Wide-Ranging Experience

General A&E provides precision sheet metal fabrication services tailored to industry-specific needs. Our team is highly experienced in serving the military, aerospace, medical, and consumer electronics industries.

Military

The military and defense industry requires components that meet strict tolerances and can withstand intense environmental conditions. Many of these components require precision fabrication processes and are used in everything from warships to combat vehicles and much more. Specialty parts, like shell casings, can also be fabricated to meet exacting requirements.

Aerospace

Aerospace components require both precision and accuracy. They must also be able to withstand high-intensity environments. Some of the most commonly fabricated parts for the aerospace industry include thermal shields, fuel system components, firewall assemblies, engine nacelles, cockpit instrumentation, and much more.

Medical

Many types of medical equipment, from operating tools to complex machinery, are produced using custom precision sheet metal fabrication services. Some of the most common applications include creating nuclear medicine cabinets, ultrasound and CT scan machine components, ablation systems, and much more.

Commercial Electronics

Commercial electronics feature numerous components that can be produced using sheet metal fabrication techniques. Enclosures, housings, brackets, cabinets, and chassis are just a few types of metal parts that are fast and inexpensive to produce using punch presses, press brakes, and laser cutting techniques. Compared to other production methods, such as extrusion or casting, sheet metal fabrication offers a lower-cost, fast-turnaround solution. Electronic devices such as computers, smartphones, smart home devices, and much more require custom sheet metal fabrication techniques.

State of the Art Machinery for Precision Execution

Our facility offers a full range of state-of-the-art fabrication equipment for handling even the most demanding jobs with skill and ease. Our sheet metal fabrication capabilities include:

- Laser cutting: Laser cutting is a highly accurate and energy-efficient method of cutting through thin or medium-gauge sheet metal. At General A&E, we use an Amada Ventis AJ-4000S laser cutting machine to fabricate parts efficiently and precisely.

- Punching: Punching techniques are performed to create precise holes in sheet metal. During the process, sheet metal is placed between a punch and a die. The punch forces itself through the sheet of metal until it reaches the die, creating a precision hole. We use an Amada EM2510 and Amada LC C1 2012 punch and laser combination machine to handle projects with speed and accuracy.

- Bending: Bending is a method of shaping sheet metal that uses a brake press machine to create V and U-shapes. The process involves placing sheet metal over a die block and pressing down on it until it contours to the desired shape. We use computer-controlled Amada press brakes to deliver fast throughout and accurate dimensional tolerances.

- Welding & brazing: Brazing is a technique for joining two metal surfaces using a brazing alloy. After the alloy is applied to the joint, it is heated to create a strong, permanent bond. Unlike with welding, brazing does not melt the base metals. At General A&E, we offer both welding and brazing processes for projects that require separate metal components to be securely joined.

Full-Service Capabilities

In addition to our primary fabrication services, we also offer a range of value-added services:

- Prototyping & Engineering: We use SolidWorks© CAD software to troubleshoot or streamline customer designs and develop prototypes. These services allow our customers to verify design concepts and evaluate product performance for a more functional and cost-effective final product.

- Assembly: In addition to our fabrication services, we also provide full assembly using fasteners or welding, depending on project needs.

- Finishing: We perform numerous finishing processes, including heat treating, powder coating, anodizing, wet paint, silk screening, stenciling, marking, chemical film application, and more. Our finishing processes accommodate the needs of RoHS compliance and MIL Spec.

Why Choose General A&E

General A&E has been providing quality sheet metal fabrication services for nearly 70 years. We pride ourselves on delivering expertly crafted metal components at competitive prices. Our facility is stocked with the most advanced fabrication technology and robotic equipment to deliver state-of-the-art production and fast throughput. General A&E is ITAR certified as well as ISO 9001:2015 and AS 9100 registered to ensure the highest possible quality standards.

Get in Touch with Precision Sheet Metal Fabrication Experts Now

No matter how rigorous your project demands are, our skilled team can meet your needs with a quality, precision-crafted component. To learn more about our custom precision sheet metal fabrication services, reach out to us with any questions. You can get your next project started by requesting a quote today.

Lasers – Turret Punch Presses

General A&E’s commitment to being at the forefront of modern technology is most evident in our blanking department. We are able to utilize this technology to its fullest by maintaining an extremely skilled and formally trained personnel.

Our flying optics laser, the Amada FO3015NT, can cut from thinner gauge aluminum parts to thicker, industrial steel parts while maintaining upmost precision and efficiency.

With a press capacity of 20 tons, 45 stations and up to 1800 hits per minute, our Amada EM2510‘s capabilities allows for speed and accuracy on a wide range of materials.

The Amada LC C1 2012 punch and laser combination machine is our newest addition. With material loading and unloading, parts picking, and lights out capabilities, the C1 is completely automated. We are able to utilize both punching and laser cutting to dramatically cut costs and lead times.

Brake – Bending

Parts with multiple bends are processed in one handling on our computer-controlled Amada press brakes to assure that they meet all dimensional tolerances after complete forming. This factory-maintained equipment is capable of keeping bending programs in memory to ensure fast throughput, though each bend is sample inspected prior to approval.